In the old Norwegian tale, "Three Billy Goats Gruff" (De tre bukkene Bruse), three male goats need to outsmart a ravenous troll to cross the bridge to their feeding ground. The valley where the three goats of the family Gruff live is sparsely covered in grass; to fatten themselves up they must make a bridge crossing to greener pasture. To do this, they face a troll, a fearsome and hideous troll who lives under the bridge and kills and eats everyone who tries to cross.

First goes the smallest of the three goats; when the troll approaches and wants to eat him, the small goat says, "Why not wait for my larger brother, a better meal?" The troll lets him pass. Next is the second goat, of medium size and more trepidatious. He convinces the troll with the same argument. The climax is the fight between the troll and the largest of the three goats: The big goat uses his horns to toss the troll into the stream. The troll perishes in the stream, the bridge is safe, and the goats get to pasture.

WE WANT OUR SALAD-SPINNERS! WHEN DO WE WANT THEM?! WE WANT THEM NOW!

You might have heard, our Eastern US port facilities are closed due to a strike. I'm a bit surprised this isn't getting more frequent and sensational coverage, to be frank. Perhaps, when the goats get hungry, they will make more noise.

The strike, impacting all the ports from Maine to Texas, is the first of its type in nearly 50 years, since 1977. Over 45,000 port workers who are part of the International Longshoremen’s Association (ILA) are involved, after a breakdown in negotiations between the ILA and the United States Maritime Alliance (USMX), representing the employers. The two chief areas of disagreement are the level of wage increases and the degree to which automation will be allowed.

It's a big deal, as these ports handle about half of US imports. Experts predict we will feel a tremendous impact on the cost and availability of goods within a few weeks. It will impact the US economy negatively, already struggling with inflation. There are also second- and third-order effects, like the impact on the US election, on China's export-driven economy, and on US holiday sales, for example.

Just as the goats want green pasture, we Americans want our inexpensive, imported goods. Our economy and our entire way of life is dependent on the continued flow of these goods. It represents our own bridge crossing if you will, complete with troll.

I'm going to lay out three arguments in this post:

The optimization of intermodal transport is a fantastic challenge, a beautiful problem in fact, one that is tailor-made to be solved by automation technology; This will happen;

The current port strike illustrates our own bridge and troll problem; we pay a toll on our imported goods, and a fight is underway to split that toll - - a pure power struggle;

Our entire supply chain faces immense challenges - - we are not competitive in this regard;

Revisiting some earlier work, Plan for Inflation & Supply Disruption!

OPTIMIZING PORT TRAFFIC FLOW IS A BEAUTIFUL PROBLEM, TAILOR-MADE FOR AUTOMATION TECHNOLOGY; THIS WILL HAPPEN

Do you remember Tetris? Maddening? Fun? Both. Soviet Computer Scientist Alexey Pajitnov developed the puzzle game in 1985, to make people happy. It went on to become one of the greatest computer games in history, with hundreds of millions of players.

Or, perhaps you've played Blokus? Beloved by parents and teachers worldwide, it is the brainchild of French mathematician Bernard Tavitian and was first released in 2000.

Both games are good for helping one develop their spatial reasoning skills, how one makes sense of objects, their shapes, and how they relate to each other. Spatial reasoning ability is not only a good predictor of future math ability but also a critical factor for success in STEM fields.

Take a look at the vessel in the photo above. COSCO Shipping's "Universe" has a dead weight of 198,000 tons, the biggest in the world, and can carry 21,237 20-foot cargo containers. That is one vessel. Imagine, if you will, your Tetris or Blokus game with twenty thousand pieces.

The coordination of the container flow is, in fact, magnitudes more complex than that, for reasons we'll explore. Let's start by thinking of the operation of a port. Your typical port has a few, basic areas of operation:

handling vessel arrivals and departures (tug boats with masters and river pilots)

handling shoreside operations (mooring and unmooring)

lifting and lowering containers vertically (with quay cranes)

moving containers horizontally (with trucks or carriers)

lifting and lowering containers in the yard (with yard cranes)

manual, tractor trailer container transport

gate operations (documents and security)

Each one of those poses its own complex challenges. Let's focus our attention on only the middle three of the seven, those most directly involved in the loading and unloading of container ships - - the grand Tetris game.

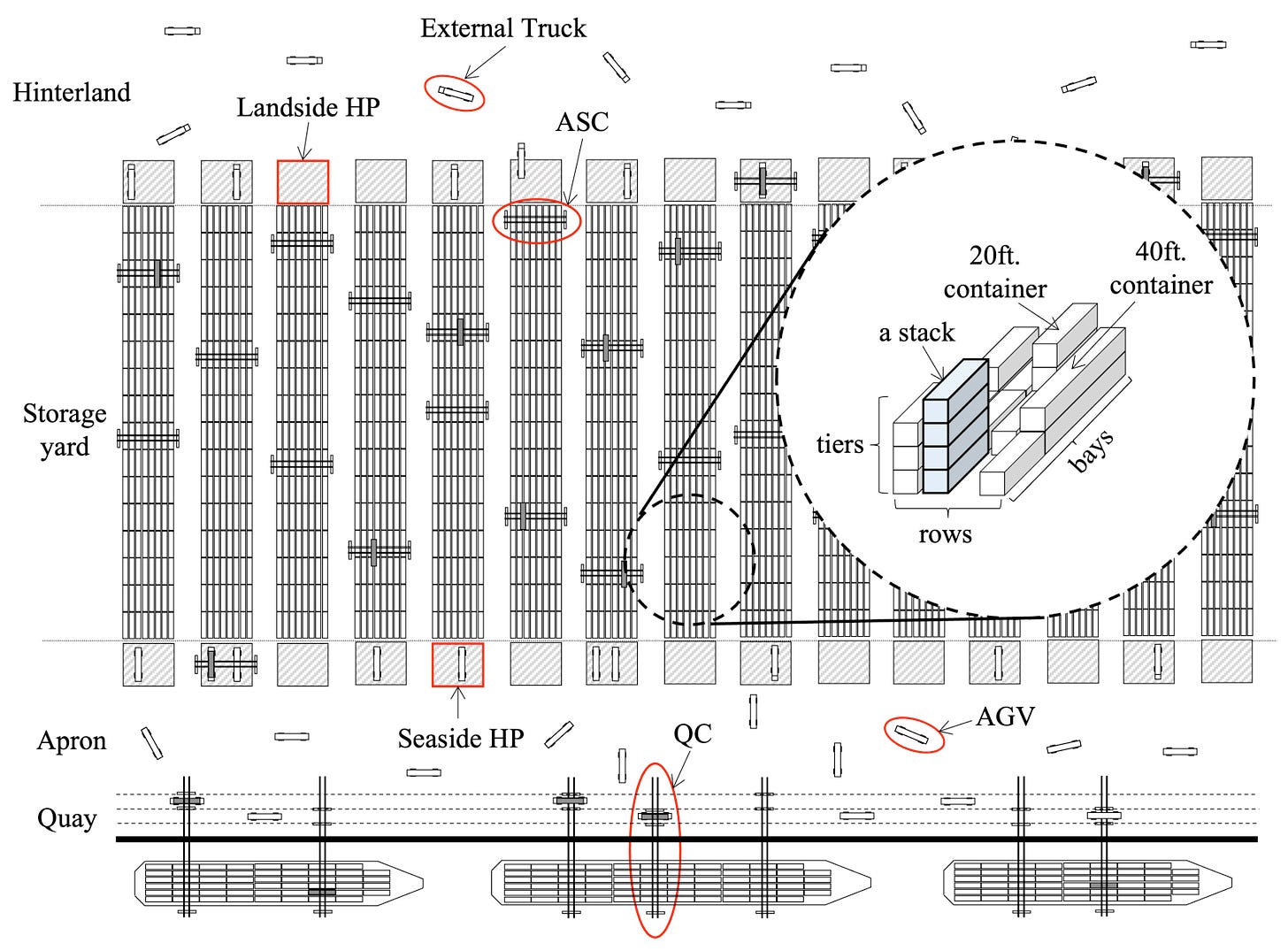

Slicing the ship like a loaf of bread, the first step is to create a stowage plan, detailing exactly what needs to go where in each standing slice, from bottom to top. In the illustration below, you see a few, bay "slices". There might be over 80 bay slices!

Do you see how it is already beginning to be a very complex problem? This is further complicated by the variety of containers, some of which, like reefers (refrigerated, perishable goods) need access to electrical power. Others, like OOG ("out of gauge"), are oddball, like a cement mixing truck or a load of giant, windmill blades. Oh, and I forgot to mention, you must put the heavy ones lower in the ship or it will fall over! The letters in the diagram indicate the destination port, here A for Antwerp, H for Hamburg, R for Rotterdam, in order of visit. Do you notice that A is above H is above R? In accounting, we call that "FILO", "First-In-Last-Out". If you don't do this correctly, you'd have to "dig out" buried items, a waste of time and effort. Visualize loading your refrigerator or freezer after a big grocery trip: Do you want to bury the salsa in the back of the fridge when you know you are making tacos tonight? Imagine that problem, one hundred times worse.

Chinese technology company Huawei has automated a number of Chinese ports. At the advanced Smart Port in Tianjin, operational since 2021, a variety of technologies, including IoT, 5G, AI, and autonomous vehicles have dramatically improved port efficiency. As just one example, the time required to plan for loading and unloading a ship has gone down from 8 hours to 40 minutes!

At Tianjin, the automated quay crane - - you've seen them from the highway, those giant monster cranes - - that loads containers into those standing bay "slices", successfully aligns the container on the first try, 90% of the time. Human operators, on ground, in climate controlled facilities, are responsible only for "exception management", that is, intervening to solve problems or issues on the small percentage of unsuccessful loadings.

Management of the storage yard, near the ships, is yet another giant, Tetris game. Tianjin yard has room for about 30,000 containers. These too must be optimally moved and stacked. Below is a typical storage yard.

In traditional terminals, dockworkers manually control the cranes themselves to ensure containers are put in right place and human drivers transport containers along same routes each day in yard operations. In Tianjin, and other automated ports - - including the Port of LA/Long Beach - - containers are moved in the yard by freely-moving Automated Guided Vehicles (AGVs). Automated straddle carriers can lift and lower containers, a job typically done by a human-driven forklift, called a reach stacker.

A 2018 McKinsey study, entitled "The future of automated ports", estimated a potential 35% productivity increase along with 55% decrease in operating expense in an automated port. The Tianjin port has experienced results in line with these forecasts: A 60% reduction in staff; a 30% reduction in cost.

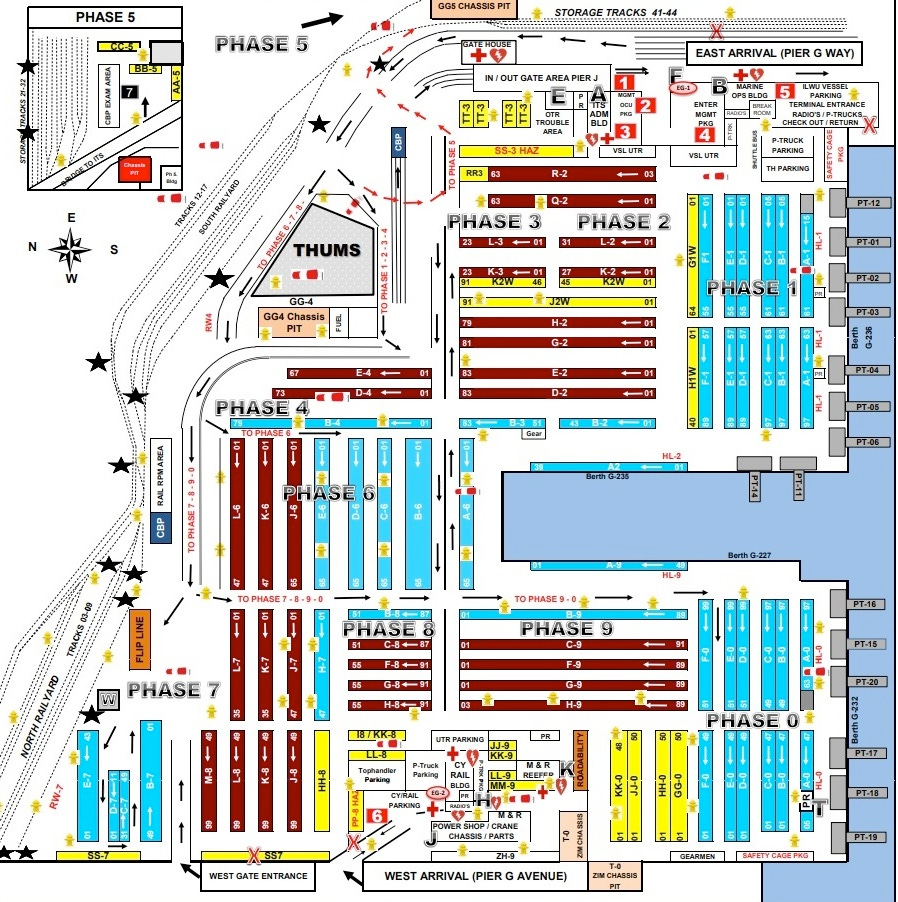

Expect that the automation trend is here for good and it will accelerate. In the map below - - a snippet of the larger Port of LA/Long Beach Map - - note the rail lines, the roads, the waterways, the signs of "intermodal" transport. This gives you insight to the scope and scale of the logistics challenge.

In our high-tech world, with fast connections, strong computer models, and networked sensors, these container loading and stacking tasks can be done 24/7, with high accuracy and very low cost. This is the future of port operations.

CURRENT EAST COST PORT STRIKE IS OUR BRIDGE AND TROLL PROBLEM - - PURE CONTEST OF BARGAINING POWER

International Longshoremen’s Association (ILA) President Harold Daggett stated in a recent video, “These people today don’t know what a strike is … I’ll cripple you. I will cripple you.” He wants higher wages for his members; he wants their jobs to remain in place and not be automated out of existence. United States Maritime Alliance (USMX), representing the employers, wants a smaller wage increase and more jobs to be replaced by automation.

Stay with me for a second. Step back and look at this in an entirely different way. We Americans - - rightly or wrongly - - off shored all of our manufacturing in order to get higher quantities of lower cost goods. We wanted cheap stuff in a hurry, and we got it, an endless bounty of "salad spinners".

Those salad spinners have to come over a bridge - - THE PORT SYSTEM. There are three bridge trolls - - THE FEDERAL GOVERNMENT, THE MONOPOLIST LABOR, AND THE MONOPSONIST PORT OWNERS. The three trolls are merely fighting over who gets what share of the toll! I'll bet you didn't see that!

Let me unpack it a bit. When an import tariff is slapped on an imported salad spinner, who gets the money? Like other federal taxes, it is collected by the importing government and goes into the general revenue account at the U.S. Treasury. They have "monopoly" power over this, no one else can do this. And then, you pay a bit more for your salad spinner.

The dock workers banded together into a group, the ILA, that linked all of the workers in the East into a single unit. That's right, they too have a monopoly - - they are the only seller of their labor to the East Coast ports. Take it or leave it - - "I’ll cripple you."

Facing that, the port owners got together and formed USMX. They bargain with the union as one buyer of the labor - - in economics, we call the single buyer a "monopsonist". This would not make a very good board game, methinks.

Thus, this strike is a wrestling match between three trolls to divide the toll they can put on our salad spinners. Who gets what will be a simple exercise in power. And, remember, the government is in the match too - - there are many federal powers that can be exercised to shape this dispute. My prediction: Expect a compromise before it gets ugly. Heck, maybe even a small tariff on some imported Chinese goods after the election?

OUR ENTIRE SUPPLY AND LOGISTICS CHAIN IS IN HORRIBLE CONDITION; WE ARE NOT COMPETITIVE WITH OUR PEERS

In research for this post, I read some dismal statistics. While Europe, Asia, and the rest of the world are rapidly improving and modernizing their ports, we lag behind. Many ports are rushing to automate EVERYTHING. Take another look at my intermodal map above. East China's Qingdao Port has built the world's first smart container transport system using elevated railways to bring containers to and from the port yard. Norway's Yara Birkeland, the world's first ever zero-emission autonomous ship, made its first maiden voyage in November 2021.

In my last post, "Amateurs talk opportunities. Professionals talk demographics." I cited as my inspiration the saying, “Amateurs talk strategy, professionals talk logistics.”, credited to General Omar Bradley. I stated in that post,

"I hemmed and hawed a bit in picking an illustration for this, as there are so many interesting ones. Take, for instance, the recent news story of the USNS Big Horn, a replenishment oiler of the United States Navy. It's more than 30 years old and recently ran aground while fueling our vessels in the Middle East. It's old, it's damaged, and we don't have a replacement. Worse, you learn when you dig a bit, this problem is an epidemic in our Navy; we've recently laid up nearly two dozen such transport ships, as WE CAN'T MAN THEM. We don't have the merchant mariners today, and we don't have them in the pipeline. This is a matter of national security."

It is bleak. Our infrastructure is old, outdated, and in decay, and there is no sense of national mission to change that. Beyond that, we have a critical shortage of warehouse space, trucks, chassis, drivers, and warehouse workers - - the whole chain is broken.

I watched a video from a young, merchant mariner, entitled something like, "10 reasons why my job stinks". Lonely, dangerous, dull, underpaid, overworked, and increasingly difficult. Something like that. Remember my line, "Amateurs talk opportunities. Professionals talk demographics." You'll need people to turn this around, if you can.

I meditated on this a bit, as well: If the three trolls have a good thing going, why fix it at all? You don't really need to, do you? The trolls probably won’t fix this.

The beneficiaries of an improved, efficient logistics and supply chain are the goats, not the trolls!

If you wanted to help the goats, you would remove tariffs and you'd break up consolidation in labor supply and port ownership - - turn it back over to local regions, perhaps the states. Let them innovate and automate as they see fit. You'd make a reinvigorated industrial base a priority, perhaps launch a new "Space Race", of a sort, with an address to Congress like Kennedy's "Special Message on Urgent National Needs".

PLAN FOR INFLATION AND SUPPLY DISRUPTION

I've been a bit obsessed with logistics for a while, and I wrote this three months ago,

"The days of speedy, low-cost, highly-reliable, international shipping are over. This is the new normal. Plan for it."

Please read the full post, and revisit it if you have. "Suck it up. Plan for Inflation & Supply Disruption"

My advice then and now, is the same: For yourself, and your organization, do this now.

1. Break up your shipments and diversify the modes of transport.

2. Diversify your sources.

3. Build your inventory.

4. Analyze your situation and plan ahead.

5. Stay informed. Stay alert.

As always, thank you for your readership. I’ve much more to say on this topic.

Nice piece, insightful.

What’s to stop the big brother goat from eating more than his share of the grass once over the troll controlled bridge?

Capital goat cannot help itself from devouring its own plot of grass then taking over the plots of his brothers even with his full belly.

Industrialization was supposed to have us all working fewer hours with increased quality of life.

Not seeing capital acting in good faith for the benefit of a better society.