Lessons from a Vacuum

I just repaired our household vacuum for the tenth time. Don't get me wrong: I love this little beast, a yellow Miele Carina. It must be 20 years old and works tirelessly.

The two-prong, electric plug broke. These plugs get tugged out, snapped into the cord reel, and stepped on; they eventually yield. It's a simple repair, taking about 15 minutes of time and a plug that is easily sourced at the local hardware store.

But what if it weren't? What if the part that breaks is hard to find, out of stock, or really expensive? Taking a closer look at a simple vacuum might give us insights about how we might plan for inflation and even supply disruption - - where things aren't available at all. [Oh, and for those of you who are thinking, "Buy a new vacuum", I touch on purchasing vs. DIY in an earlier post, "Money for Nothing. Tips for Free."]

Vacuums are pretty simple: There's a sealed chamber, a vacuum pump that depressurizes that chamber - - the 'suck', an electrical cord for the pump, and, finally, a hose for the chamber. Everything else, various nozzles, wheels, handles, cord reels, et cetera, are to add convenience for you, "creature comforts".

Once, when the push button “on / off” foot switch broke, I tore the entire machine apart, cleaned it thoroughly, replaced the switch, and reassembled "her": I know "Carina" well. With that, let me assert: There are three mission-critical parts in Carina: The pump motor, the control circuit board, and … wait for it … the vacuum bag(s). I could even argue that there are only two critical parts, as the circuit board is very simple, so an industrious person could troubleshoot and fix it as well.

You could, if you had to - - and I've done it before - - bypass the foot switch, use an extension cord in place of the cord reel, and duct tape a salvaged hose on to a vacuum to get it to work. But, you have got to have a running pump motor and the bags - - and the best vacuums do indeed use bags. Nothing else matters. When I buy a new vacuum - - my latest a Festool Cleantec "dust extractor" - - I always buy at least a year's worth of bags, and you should too. Bagless, a vacuum is useless, silently occupying space.

Walk around your house, walk around your organization. Are there things that you use every day, things that make your life much better, that rely on a simple, critical part to do so? Having that critical part on hand NOT ONLY hedges you against the increasing cost of that part BUT ALSO might make this machine usable for years, if that critical part is suddenly unavailable. A hedge against "supply disruption." Source those parts NOW.

Why am I talking about this? Remember COVID and that supply disruption?

Conflict Is Creating a Worldwide Supply Shock

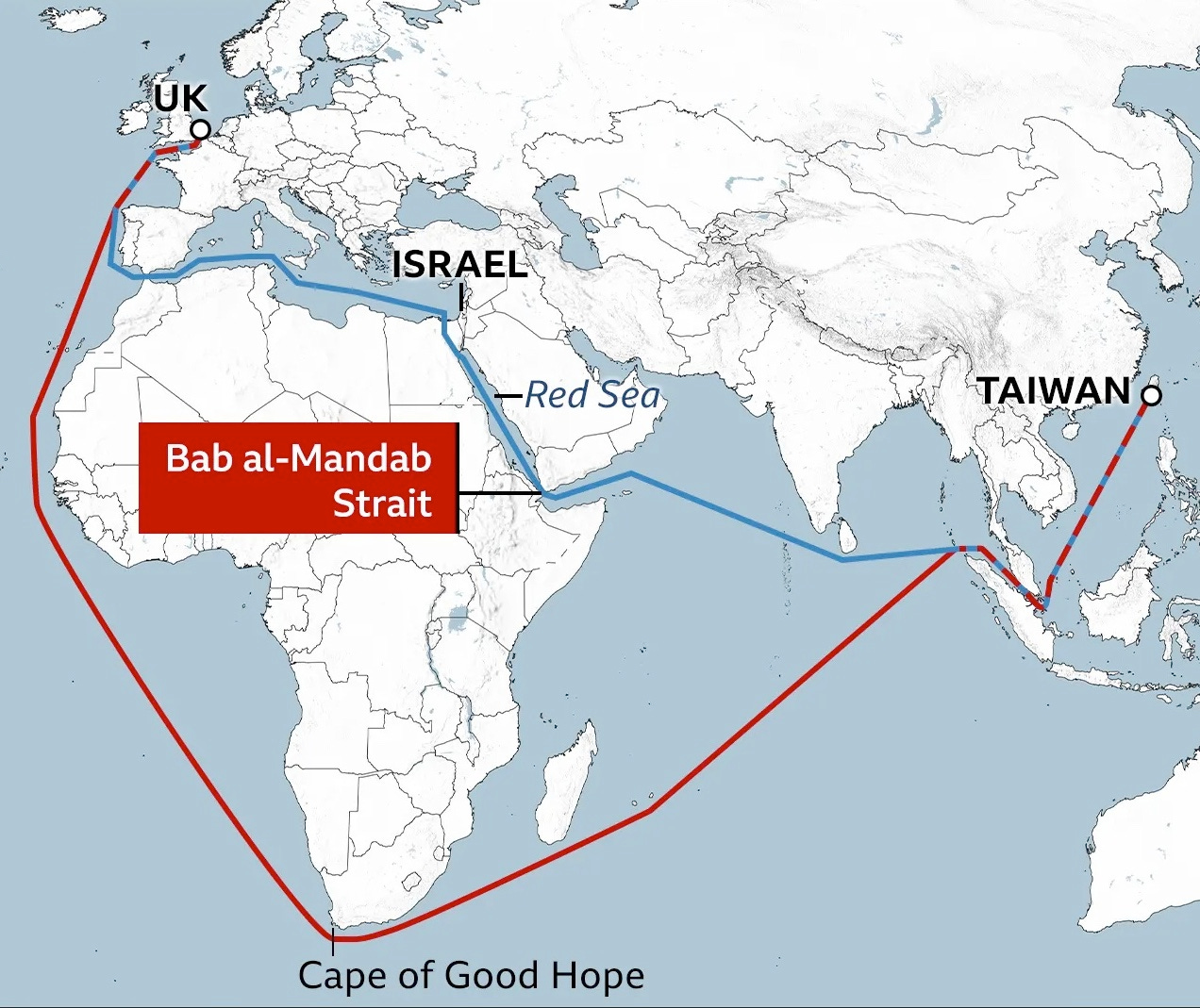

Since this spring, the Israel-Hamas war has led the Iran-backed Houthis to freeze the critical maritime chokepoint of the Bab al-Mandab Strait connecting the Suez Canal. They have done this by attacking Western commercial vessels with missiles and drones. Major shipping operators have been forced to reroute containerized freight around the Cape of Good Hope, the southern tip of Africa, straining shipping capacity and dramatically increasing costs.

A journey from Taiwan to the UK normally takes a container vessel about 25 days, 10,000 miles. It now takes ten days more, covering an additional 3,500 miles - - 40 percent more time, 35 percent more distance!

About half of the world's trade flows through this and three other checkpoints, in Panama, in Hormuz, and in Malacca. A conflict between China and Taiwan would certainly impact the Malacca checkpoint in the South China Sea. Were Iran to be drawn into the Middle Eastern conflicts, Hormuz will feel it. Increased tensions between the BRICS bloc and the West draws the Panama Canal into play as well. The days of speedy, low-cost, highly-reliable, international shipping are over. This is the new normal. Plan for it.

Another quick anecdote. A friend has a side gig where he repairs commercial toaster ovens at a nationwide restaurant chain. The ovens are absolutely critical: If the oven won't work, food production stops. No sandwiches. Having owned several of the franchises himself, my friend knows the issues - - he knows the ovens. I asked him, yesterday, in preparation for this post, "Are there two or three, or five, critical parts?". He said yep. "Where are you getting those?" He told me "ovenpartsfrommars dot com" or something like that. I replied, "Country of origin?". He, "Taiwan". He told me he has ovens, sitting in his workshop that have been waiting THREE MONTHS for parts! The owners of these restaurants have to cannibalize other broken ovens for working parts OR buy a new, spare oven - - while they still can!

Disruptions will Drive Price Increases Until they Drive Outages

You will feel this in your home. You will feel this in your workplace. Prices will go up and up. Your wait times will grow long and longer. One day you might not get items at all.

I've mentioned before I ran a production line at Toyota. We optimized our lines and transit: We were famous for it! "Just-In-Time" inventory management, "JIT". We conducted a worldwide symphony of parts flow, tens of thousands of parts from thousands of vendors. It was so efficient and effective that everyone else copied us and went to similar systems. Guess what. The world has never tested how well JIT works in a world of conflict - - only peacetime "happy days".

Nice plane you got there, Maverick, until you don't have parts for it!

"If we were in a war with China and it stopped providing parts, we wouldn't be able to build the planes and weapons we needed…" - U.S. Army Major General John G. Ferrari

The United States Military is entirely dependent on long, peacetime supply lines and parts from China!

"You can't just turn around on a dime because the [manufacturing] capacity doesn't exist here.[!]" - Ferrari

The US has gotten itself into a bind. Years of offshoring manufacturing - - driven by a desire to cut costs - - have left us critically dependent on others. It's risky and especially so in an unstable world. I intend to dedicate further posts on this and other costs of complexity.

For yourself, and your organization, do this now.

Break up your shipments and diversify the modes of transport. Is there something you ship to others or that is regularly shipped to you? Consider breaking the order into two orders. Perhaps one half that is shipped your usual, speedy method and the other half you choose "Ground. Three weeks.", or the like. You might be able to do this at equivalent cost and you have hedged yourself against the risk of the item not being received, shipper risk.

Diversify your sources. Remember my oven friend? Where else could he get electrical transformers and blower motors? It's important that you develop a deep bench of players when it comes to suppliers for things you need, especially mission critical items. Develop those sources now. And, develop now the practice of splitting your next order across a couple of vendors, hedging yourself against yet another risk, supplier risk.

Build your inventory. By having more on hand, you give yourself resilience from supply disruption. It is a good inflation hedge as well. I gave the example of the vacuum bags above. For many complex machines, like cars, for example, the items to stock are specialized oil or air filters. These are often make-, model-, and year-specific items and are often only available from a single manufacturer or supplier! Risky.

Analyze your situation and plan ahead. I made the Tacoma truck at Toyota (then called the HiLux). One day at the plant we were invited into an empty warehouse. There on the concrete was - - torn into a thousand pieces - - a rival manufacturers truck. Every single component part, panel, and fastener lay before us to examine, as in the car photo above. You need to visualize your home, your organization in this manner - - exploded parts view. What is critical? What are those processes, those parts? What can you do to minimize those risks? Think. Overheard a couple of friends chatting the other day, and one said, "Thinking of getting a mini-split heat pump." My inner dialog was, "Wow, complex machine with a thousand parts sourced from the other side of the world. Egad!" My oven buddy said, "I like fans." Do you see!? A fan has an elegant simplicity; it also has substitutes, spares, redundancies - - a heat pump does not! Be leary of making yourself or your organization reliant on complex solutions, especially now.

Stay informed. Stay alert. Never has it been more important for you and your organization. Track your packages. Observe. Listen. React. Be fastest and first. This is something I will explore in far greater depth in future posts.

Do you have other thoughts on how to mitigate the higher costs of goods? Other ideas on how to mitigate supply disruptions? Please share in the comments below.